SPIN KLIN DISC FILTER

Rosenwach, a trusted New York icon for more than 150 years, has teamed up with Arkal, an industry leader in water filtration. Together, we offer an extensive line of water filtration systems to assure that you'll get the right solution for your building's needs. By installing an innovative, reliable, and efficient Rosenwach system, you'll have less hassle and less headaches all the way around. The innovative selfcleaning system effectively and proficiently captures large amounts of unwanted solids and automatically flushes them to drain. By doing so, your new operating sysiem will have a longer, healthier life - requiring less maintenance and cleaning and your residents will enjoy clean, clear water. Call Rosenwach today and let us help you filter out unexpected and unwanted costs and increase your building’s value. Cleaner water means a cleaner tower, cooler water and significant savings. Rosenwach provides the best clean water solutions in the field.

Rosenwach Spin Clean brings disc filtration technology to the cooling tower industry. Disc filtration technology uses specially designed grooved discs to create valleys between each disc to trap solids. Cleaning is accomplished when the discs are separated and water is backflushed through them, removing the solids. The process can be automated and consumes low water and low energy.

• Uniquely efficient

• Precise particle separation

• Innovative filter design captures and stores large amount of solids

• Low energy and water consumption

• Long-term operation with minimal maintenance

• Operation is easy and requires no filter media replacement

• Continuous flow during backwash

• Corrosion free

• Scalable modular system

• Can be used where backwash filters get blocked

FILTRATION PROCESS

Color-coded polypropylene discs are grooved on both sides to a specific micron size. Multiple discs are then stacked and compressed on a specially designed spine. When stacked, the grooves on top run opposite to the grooves below, creating a filtration element with intersecting grooves which trap the solids. The stack is enclosed in a corrosion and pressure resistant housing. During filtration. the discs are tightly compressed together by a combination of a spring and the differential pressure, thus providing high filtration efficiency. Filtration occurs as water flows from the outer diameter to the inner diameter of the disc stack.

BACKFLUSHING PROCESS

Activated by a predefined command (differential pressure or time) Spin Klin modules are backwashed sequentially. The valve inlet part shuts as the drain port is opened. During the backwash process, the disc compressron is released. The spine piston rises up, releasing the pressure on the discs. Tangenital jets of clean water are pumped at high pressure in the opposite direction through nozzles at the center of the spine. The discs spin free and clear, loosening the trapped solids. Solids are quickly and efficiently flushed out to a waste drain.

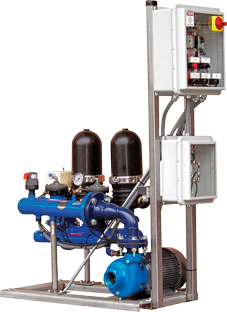

CUSTOM CONFIGURATIONS

Spin Klin is a highly configurable and customizable system that can be tailored to your specific needs. Below is a chart of the basic modular systems.

• shown: battery of 3

• up to a battery of 6

• up to 140 gallons per minute

• shown: battery of 3

• up to a battery of 8

• up to 282 gallons per minute

• shown: battery of 6

• up to a battery of 8

• up to 755 gallons per minute

TECHNICAL DATA

• Filters to less than 10 microns

• 145 psi maximum operating pressure

• 50 psi minimum backwash pressure

• Available in full flow or side stream configurations